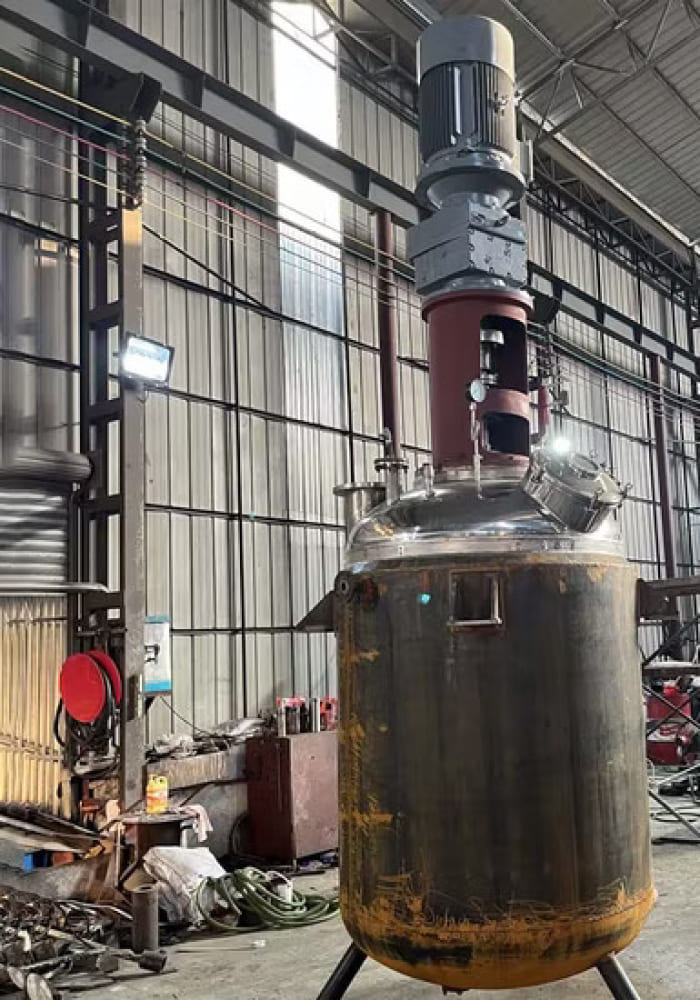

Chemical Reactors by Janardan Metal Industries

Precision-Engineered Vessels for Safe, Efficient, and Controlled Chemical Processing

At Janardan Metal Industries, we specialize in the design and fabrication of high-performance chemical reactors for a wide range of industrial applications. Built with precision, durability, and process control in mind, our reactors are engineered to handle high pressures, corrosive media, and demanding thermal conditions, ensuring consistent, safe, and scalable chemical reactions.

What is a Chemical Reactor?

A chemical reactor is a pressure-rated vessel used to carry out chemical transformations in controlled environments involving temperature, pressure, mixing, and reaction time. Reactors play a critical role in the pharmaceutical, petrochemical, food, and specialty chemical industries, where product yield, quality, and safety are paramount.

Key Features of Our Chemical Reactors:

Robust Construction Fabricated from SS 304, SS 316, Hastelloy, or carbon steel depending on chemical compatibility and process requirements. Reactor shells are rated for high-pressure and vacuum conditions.

Custom Configurations Available in batch or continuous flow models with a wide range of capacities (from 100 liters to 50,000+ liters). Custom sizes and geometries can be designed as per plant layout and process needs.

Agitation and Mixing Equipped with top or bottom-mounted agitators, including anchor, paddle, turbine, or magnetic stirrers for optimal mixing, dispersion, and heat transfer.

Heating & Cooling Options Integrated jacketed or limpet coil systems for steam, oil, or water-based thermal control, ensuring precise temperature regulation throughout the reaction cycle.

Sealing & Pressure Control Designed for gas-tight operation, with pressure-rated lids, safety relief valves, rupture discs, and optional vacuum operation capabilities.

Quality & Safety Standards

Machined on precision CNC equipment for perfect fitment and surface finish

Dimensional accuracy verified with digital micrometers and verniers

Weld integrity tests:

Dye Penetrant Testing (DP)

Radiographic Testing (RT)

Ultrasonic Testing (UT) on critical joints

PMI testing on incoming raw materials for chemical resistance assurance

Hydrostatic and pneumatic testing conducted in-house or by certified third-party agencies

Fully compliant with ASME, IS, and GMP standards, with IBR certification available when required.

Optional Accessories:

Condensers, receivers, dosing tanks

Sight glasses, pressure gauges, and level indicators

Digital temperature and pressure control systems

CIP/SIP systems for sterile applications

Explosion-proof motors and flameproof electricals for hazardous zones

Applications:

Pharmaceutical & API Manufacturing

Dyes, Pigments & Paints

Petrochemical and Refining Industries

Food Additives & Flavoring Agents

Polymer and Resin Manufacturing

Specialty and Fine Chemicals

Janardan Metal Industries - Engineered Reactors for Precision Chemical Processes

With a focus on safety, quality, and custom process needs, our chemical reactors are trusted by industries for batch consistency, operator safety, and process scalability. Backed by decades of experience and advanced fabrication capabilities, Janardan delivers performance you can rely on.