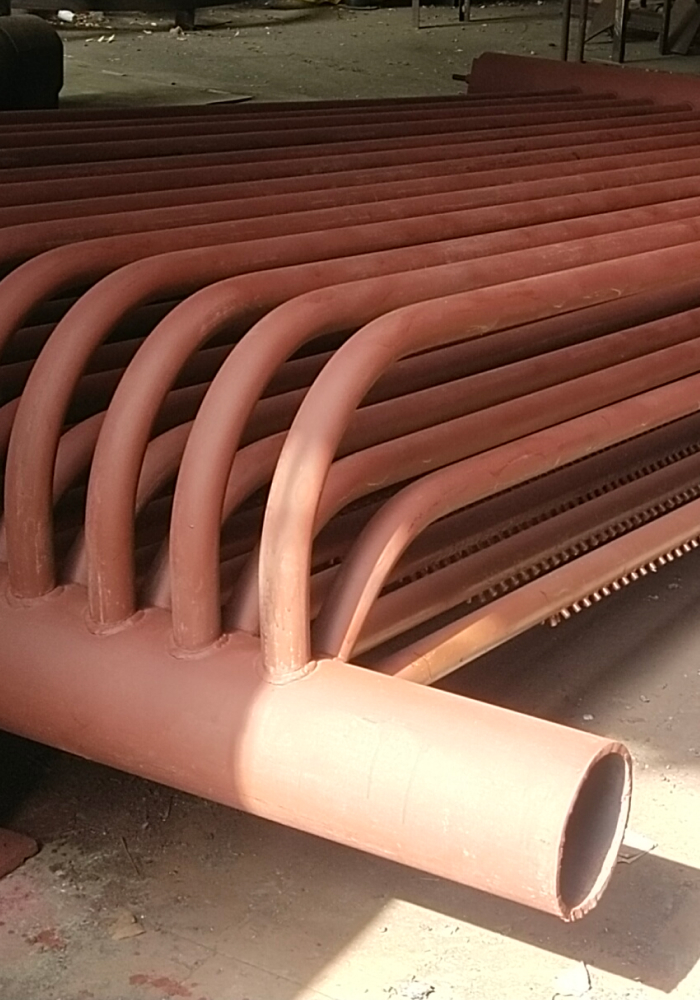

Specialised Pipe & Coil Bending Services by Janardan Metal Industries

Precision-Bent Pipes and Coils Engineered for Performance, Strength, and Exact Fitment

At Janardan Metal Industries, we offer specialised pipe and coil bending services tailored to the needs of critical engineering applications. Whether it’s for process piping, heat exchangers, condensers, boilers, reactors, or custom fabrication jobs, our in-house capabilities ensure tight-radius, smooth-surface, and dimensionally accurate bends with minimal deformation and thinning.

What We Offer

Our bending facility caters to a wide range of diameters, thicknesses, and materials, supporting both standard and complex custom geometries including:

U-bends

Spiral coils

Helical coils

Multi-plane bends

Hairpin and serpentine coils

Concentric and eccentric coil designs

Technical Capabilities

Pipe Sizes: From 6 mm to 100 mm OD

Bend Radii: As low as 1D (tight radius) depending on pipe size and material

Materials Handled:

Stainless Steel (SS 304, SS 316, Duplex)

Carbon Steel

Copper and Brass Tubes

Aluminium and Special Alloys

Bending Techniques:

Mandrel Bending for smooth, wrinkle-free curves

Roll Bending and CNC Bending for precise, repeatable forms

Cold and Hot Bending as per material behavior

Quality Control & Testing

Precision measurements with digital verniers and micrometers

DP Testing (Dye Penetrant) for surface crack detection

PMI (Positive Material Identification) on all incoming pipes

Hydrotesting and pneumatic testing on bent coils and assemblies

Radiographic testing (RT) for critical weld zones if welding is required post-bending

All jobs executed to IS, ASME, and custom client standards

Applications:

Heat Exchangers and Condensers

Boiler Coils and Steam Generators

Reactor Jackets and Limpet Coils

Distillation Columns and Tank Piping

Water-Cooled Furnace Hoods

Chemical Process Systems

Automotive and Aerospace Tubing

Why Choose Janardan:

High repeatability and accuracy on rotary draw bending machines

In-house tooling and dies for quick custom setups

Ability to execute complex coil shapes and multi-bend assemblies

Fabrication-ready delivery with optional welding, flaring, threading, and end preparation

Janardan Metal Industries - Precision in Every Curve

Whether it’s a single custom piece or a full-scale industrial piping assembly, Janardan Metal Industries delivers pipe and coil bending solutions that are dimensionally accurate, leakproof, and ready for immediate integration. Our deep experience and strong technical infrastructure make us the trusted choice for clients across chemical, pharmaceutical, thermal, and fabrication sectors.