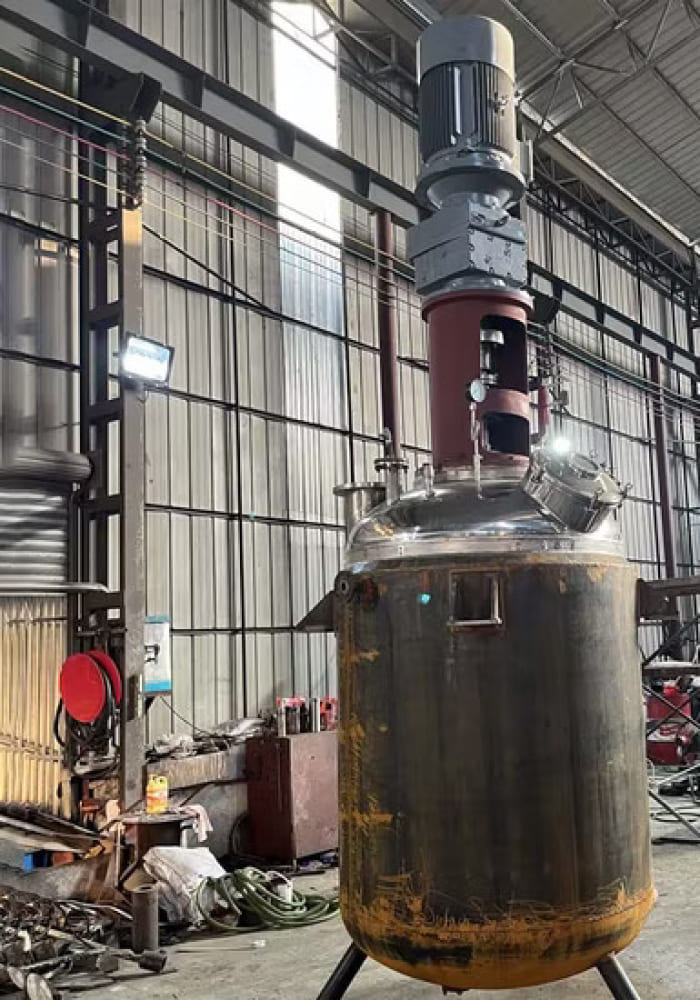

Chemical & Utility Tanks by Janardan Metal Industries

Durable Storage Solutions Customized for Your Needs

At Janardan Metal Industries, we manufacture a wide range of chemical and utility tanks designed to provide safe, reliable, and long-lasting storage solutions for industrial, chemical, and process applications. Built to exact specifications, our tanks cater to diverse requirements—from aggressive chemicals to general utility fluids—ensuring operational safety and efficiency.

Tanks Types

Types of Tanks We Manufacture:

Chemical Storage Tanks Engineered to store corrosive and hazardous chemicals with appropriate material selection and protective linings to prevent contamination and degradation.

Process Tanks Customized tanks for intermediate and batch processing with options for mixing, heating, and cooling.

Water & Utility Tanks Customized tanks for intermediate and batch processing with options for mixing, heating, and cooling.

Specialty Tanks Including pressure-rated, insulated, and lined tanks for unique application needs.

Features

Key Features of Our Chemical & Utility Tanks:

Material Versatility Fabricated from carbon steel, stainless steel (SS304/SS316), mild steel, or alloy metals based on the stored media and operational conditions.

Custom Sizes & Shapes Cylindrical, rectangular, or specialized shapes with volumes ranging from small vessels to large industrial tanks.

Compliance & Safety Designed to meet IBR, ASME, and client-specific standards, with appropriate safety features such as venting, manholes, and level indicators.

Corrosion & Leak Resistance Surface treatments including coatings, linings, and passivation to extend tank life and maintain integrity.

Ease of Access & Maintenance Fitted with manways, nozzles, ladders, and access platforms for safe operation and inspection.

Manufacturing Excellence & Quality Assurance

Precision Fabrication with advanced tools like digital vernier calipers and micrometers for exact measurements.

-

Strict Quality Control including:

Dye Penetrant Testing (DP) for weld surface integrity

Radiographic Testing (RT) to inspect weld joints

Positive Material Identification (PMI) testing to verify material grades

All testing is coordinated in-house through certified third-party agencies, ensuring full compliance and traceability.

Applications

Industries Served:

Chemical and Petrochemical Processing

Food & Beverage Processing

Pharmaceutical Manufacturing

Water Treatment & Waste Management

Paints, Dyes, and Coatings Industry

General Industrial Utilities

Janardan Metal Industries - Custom Tanks Engineered for Reliability and Safety

Whether you require standard storage tanks or complex process vessels, we offer custom solutions built with quality materials, expert fabrication, and rigorous testing to meet your exact needs.